JAM MARMALADE PROCESSING LINES

Complete lines for fruit processing

Jam and marmalade production line

Mymak Proses provides complete jam and marmalade production line. Our state-of-the-art processing line is meticulously designed to streamline every step of the production process, from ingredient mixing to filling and packaging, ensuring efficiency, consistency, and superior quality in every batch.

Crafted with precision and ingenuity, our line integrates cutting-edge technology with the expertise of food engineering, ensuring seamless operations and unparalleled product quality.

Invest in Excellence

Elevate your jam and marmalade production to new heights with Mymak Proses’ complete jam and marmalade production line. Contact us today to learn more about how our equipment and expertise can benefit your operation.

Jam and Marmalade Processing Line

Explore Our Complete Jam and Marmalade Production Line

Jam and Marmalade Production Process Equipment

Capacity: 1000 KG/H

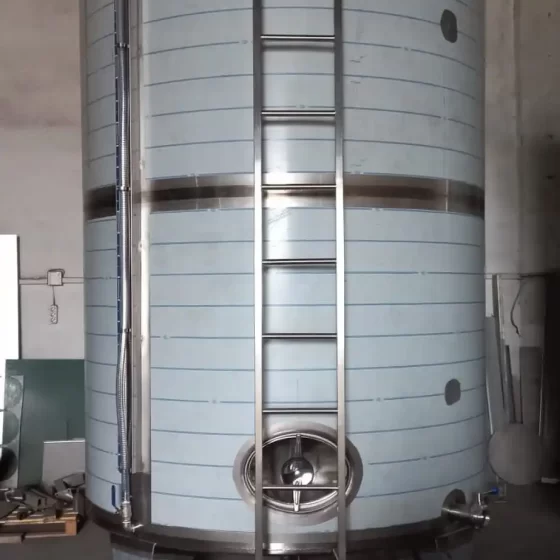

- Glucose Tank

- Glucose Heating Exchanger and Pump

- Premix Boiler

- Pectin Mixer

- Vacuum Boiler

- Filling Boiler

- Feed Rotary Tray

- Sterilized Tunnel

- Automatic Filling Machine

- Automatic Capping Machine

- Pasteurized & Cooling Tunnel

- Drying Line

- Security Band Tunnel

- Automatic Labeling Machine

- Date Coding

- Rotary Tray

- Shrinking Machine

- Steam Generator

- Cooling Tower

- Air Compressor

Do you need detailed information about processing lines?

View our products in action